|

|

| Your Location: Home>> Machine |

|

DT model of AUTOMATIC SEAMLESS JACQUARD KNITTING MACHINE

|

|

DT model of AUTOMATIC SEAMLESS JACQUARD KNITTING MACHINE, based on the traditional band crochet, is to replace the hand with machines in operation and human thinking with computers. After some renovation, a latest model of automatic knitting machine is produced. It can well imitate the hand knitting and weave all kinds of laces, with a quality and unification of the laces that cannot be reached by any hand knitting. Laces produced by this kind of machine are widely used on all kinds of slap-up costumes, under-wears, curtains, shoes & caps and bed clothing and are wel-laccepted.

Our machines use the acvanced control computer for industry, fully automatized and intelligentized.

Our machines have an ingenious structure with fine quality parts. The new design is free from the old mechanical paper card technique and the related mechanical driving setup, thus making it more reliable in operation with few malfunctions. The laces produced by this machine are fine and beautiful. And the lace may manufacture the single design circulation to surpass 10,000 cards. Which cannot be achieved by the old mechanical machines. |

A computer design system is collicated with this machine, with which the lace design work becomes easy and simple. Therefore, production efficiency id greatly improved and production cost is greatly reduced.

The machine can us all different kinds of material for knitting, for example, pure cotton, hemp, silk, wool and all kinds of chemical fibers. It needs no accessorial equipment to start production, which results in little investment but fast benefit.

We would like to express our gratitude hereby to all our customers. Meanwhile, we guarantee to you that we offer free training for the use and repair of the machine once you decide to use our machines. |

|

|

|

|

It features automatic computer control, variable frequency speed control, high speed &high efficiency and easy operation; used to knit various high grade underwear, garments, table cloth, curtains, sofa cover, beddings, toys etc; can used raw materials, like cotton, flax, nylon, polyamide fibre, polyester and synthetic fibre

|

|

- Display and control box

Large-screen Colour LCD, advanced computer program, easy operation and control. Can greatly reduce labor, shorten the changing time of patterns and greatly increase production efficiency.

- Weaving parts

High-strength wearable new type materials is used; features low vibration, low noise, high speed, large produciton capacity.

Intelligentized control, no manual operation needed. More precise rolling wider range.

|

|

|

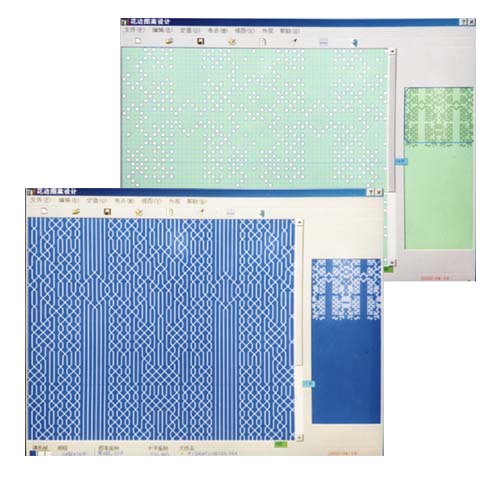

- The lace design system

The design system with strong and perfect function can satisfy various kinds of request of the designer. It makes the designer free out from the superfluous design in great numbers. The design work without paper makes the type of flower. The design work wothout paper makes the cost reduce too. involve effciency to improve, the design cycle acelerates. More easy to manage.

|

- The pulling force tester of spring

The pulling force tester of spring is intelligent tester. It based on high stability sensor and single. It has count apparent, function of restoring to the throne since relatively, memory trouble show etc accurate measurement operating simple, multilple functionally.

|

|

|

Performance Data |

Model NO. |

DT-64 |

DT-96 |

Qty of spindle |

64 |

96 |

Max width of ruffle edge |

150mm |

250mm |

Weaving speed |

300ka/min. |

Main motor |

0.75kw/380v(3 phases) |

1.5kw/380v(3 phases) |

Take-up speed |

0.01~3mm |

Power Supply |

220v(single-phase) |

|

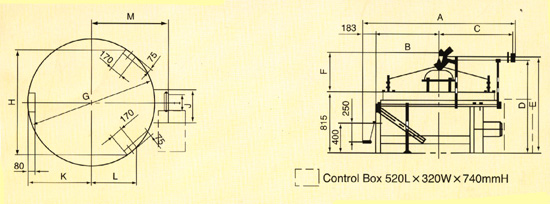

Shape parameter |

Type |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

DT-64 |

1641 |

630 |

795 |

1193 |

1241 |

465 |

1256 |

1101 |

140 |

375 |

628 |

439 |

825 |

DT-96 |

2101 |

860 |

1025 |

1258 |

1306 |

530 |

1716 |

1428 |

215 |

450 |

858 |

607 |

1055 |

|

|

|

|